Chetolah Creek WRRF Improvements

Delivery Method

Design-Build

Client / Owner

City of Hays, Kansas

Engineers

Burns & McDonnell / HDR

CAS Constructors and design-build partner, Burns & McDonnell, upgraded the City of Hays, Kansas’s Chetolah Creek Water Reclamation and Reuse Facility to replace aging infrastructure and meet stricter discharge limits from the Environmental Protection Agency (EPA) and Kansas Department of Health and Environment (KDHE). The existing facility was originally constructed in 1953 and had most recently been upgraded in 1993, and approximately one-third of the plant’s installations exceeded their service lives. Upgrades to the plant included the construction of a new liquid process train, improvements to the biosolids treatment process, complete electrical upgrades, and expansion to the city’s reuse storage capacity.

The CAS Constructors team demolished unused portions of the existing plant to build a new liquid process train. At the beginning of the new liquid process train, a new influent pump station and headworks building was installed. Inside the headworks building, trash removal is done via new drum screens and grit removal is completed using newly installed headcells, along with grit washing and classifying. The process train also includes a single 185-foot diameter aeration basin that contains four submersible mixers and 24 submersible air diffusers, two 75’-diameter primary clarifiers, and a tertiary disc filter housed in a new building. Finally, the existing sand filter room was retrofitted for primary disinfection with four new UV in-line chambers.

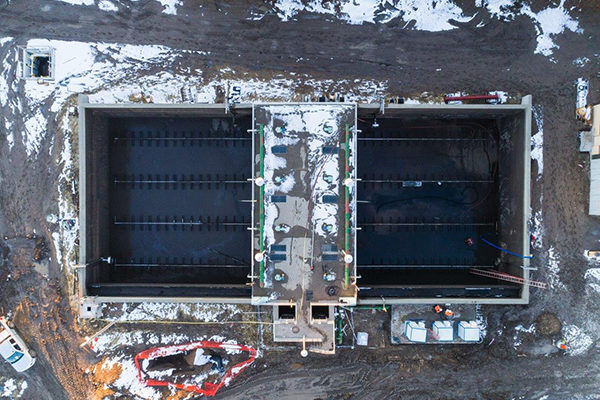

To treat biosolids, the CAS Constructors team converted two existing aeration basins to digesters and installed new sludge pumps that pump to a new centrifuge. The solids are dewatered in existing drying beds and finally land applied.

The City of Hays was unable to agree to a guaranteed maximum price with their original design-build team, leading the City to take the job back to the market for fixed-priced design-build bids. The CAS Constructors joint venture generated multiple cost savings ideas, allowing the City to complete the project for $4 million less than the original design-builder’s guaranteed maximum price. Accepted cost savings ideas included a different approach to the new liquid process train, selective repurposing of existing processes, and expanding an existing water reuse pond at the City’s golf course, rather than adding large water reuse storage tanks at the wastewater treatment facility.